Maker resources

Are you a maker who wants to get started making PPE? Refer to the links below to see which designs out community is making. You will generally need some of the following equipment: Laser cutter, 3D printer, sewing machines and minimal shop tools.

The following PPE can be manufactured with these tools: 100% Cotton Masks and Face Shields

If you are planning on making PPE. You must understand the risks.

Read more about your responsibility.

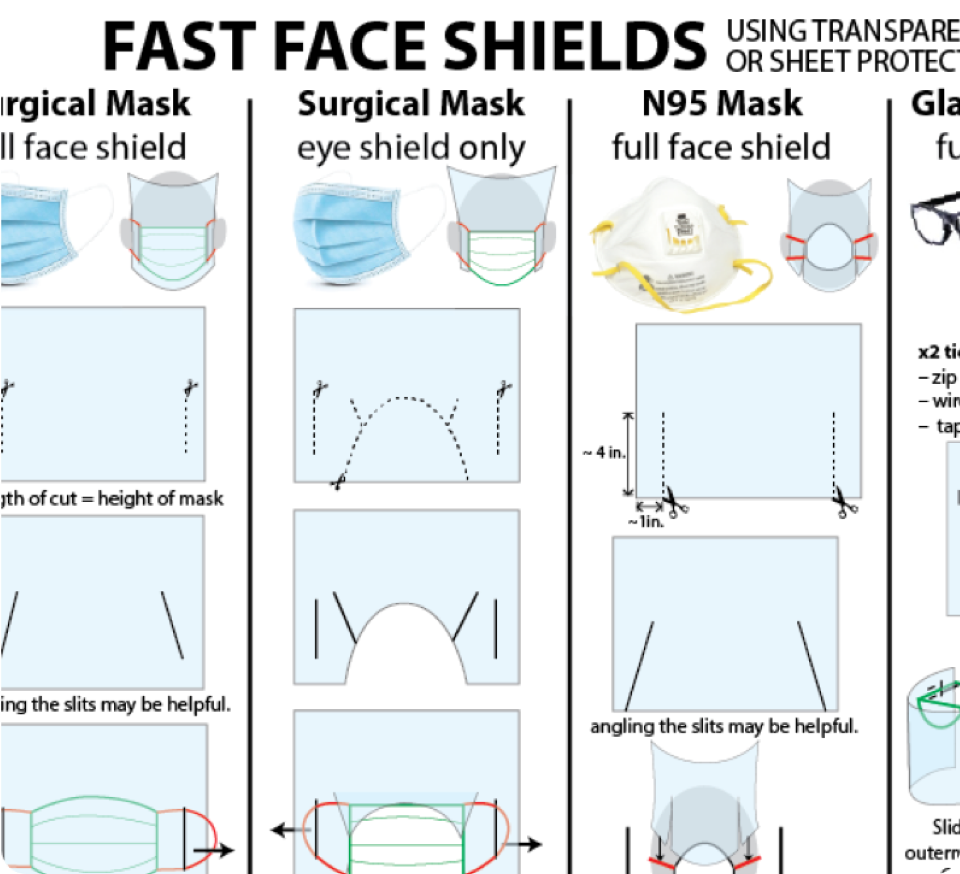

Face Shields

Face shields are worn by doctors and nurses when intubating patients to prevent fluids from contacting their face. They are often worn on top of N95 masks, and protects both the user and the mask. Face shields can be manufactured easily with 3D printing, laser cutting plastic sheets, or potentially die-cutting plastic sheets.

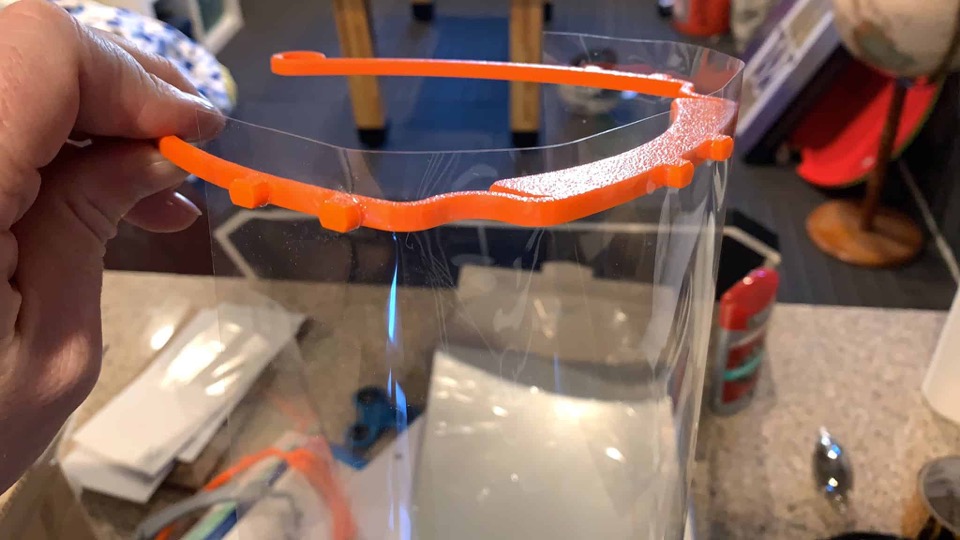

3DVerkstan Face Shield

This is currently our preferred 3DP design.

| It uses a glasses-like design, and does not require foam or elastic parts. It is designed for plastic from a sheet protector, with holes punched with a standard hole puncher. |

|---|

Models can be downloaded from here: [external link]

Instructions for final assembly can be found here.

WISC

| This is a face shield manufactured from a plastic sheet, foam tape, and elastic. This design takes far less time to manufacture, but is disposable due to the unsanitizable foam. |

|---|

Resources

- Main website: [external link]

- Delve post: [external link]

- Design PDF: [external link]

Materials can be sourced directly from McMaster-Carr, but alternatives are fine.

- Plastic: [external link]

- Foam: [external link]

- Elastic: [external link]

- Staples

Our members are actively manufacturing this design.

Open Source Face Shield

| This is a face shield design by the NYU COVID-19 Task Force. It is manufactured from a plastic sheet and elastic. A well-placed plastic forehead piece prevents the need for a foam spacer. |

|---|

The design is available here: [external link]

Prusa RC2

| Designed by Prusa Research, this design involves 3D printed parts, a laser cut face shield, and an elastic backing. |

|---|

Resources:

- Blog post: [external link]

- Design: [external link]

Companies are also printing and selling this design.

- Shapeways is selling just the 3DP parts for $40 [external link]

- Voodoo Manufacturing will be selling the completed shield for $10 at bulk [external link]

While this may be the most durable design, the output may be too slow to meet the demand in NYC. It takes about 2~3 hours to print each headband part, which is too slow.

Budmen

| This is also a 3D printed design by Budmen Industries. Requesting or manufacturing the design requires registration. [external link] |

|---|

Fabric Masks and Respirators

We don't recommend 3D-printing masks and respirators. This blog post by Prusa explains it well.

However, sewn masks can be worn individually or over N95 masks for added protection. We list available designs below. These masks are not meant to be replacement for surgical or medical grade equipment.

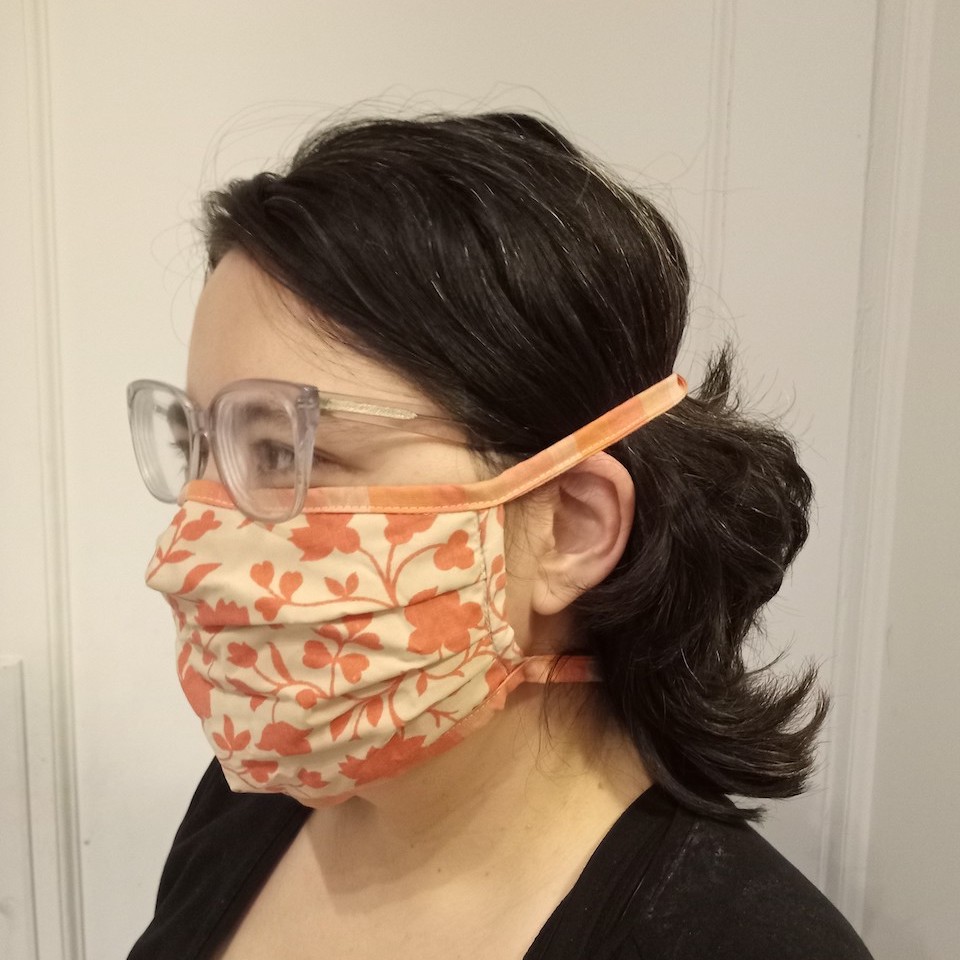

Sewn 100% Cotton Masks

This is currently our preferred mask making protocol and patterns. Along with the info sheet for healthcare workers.

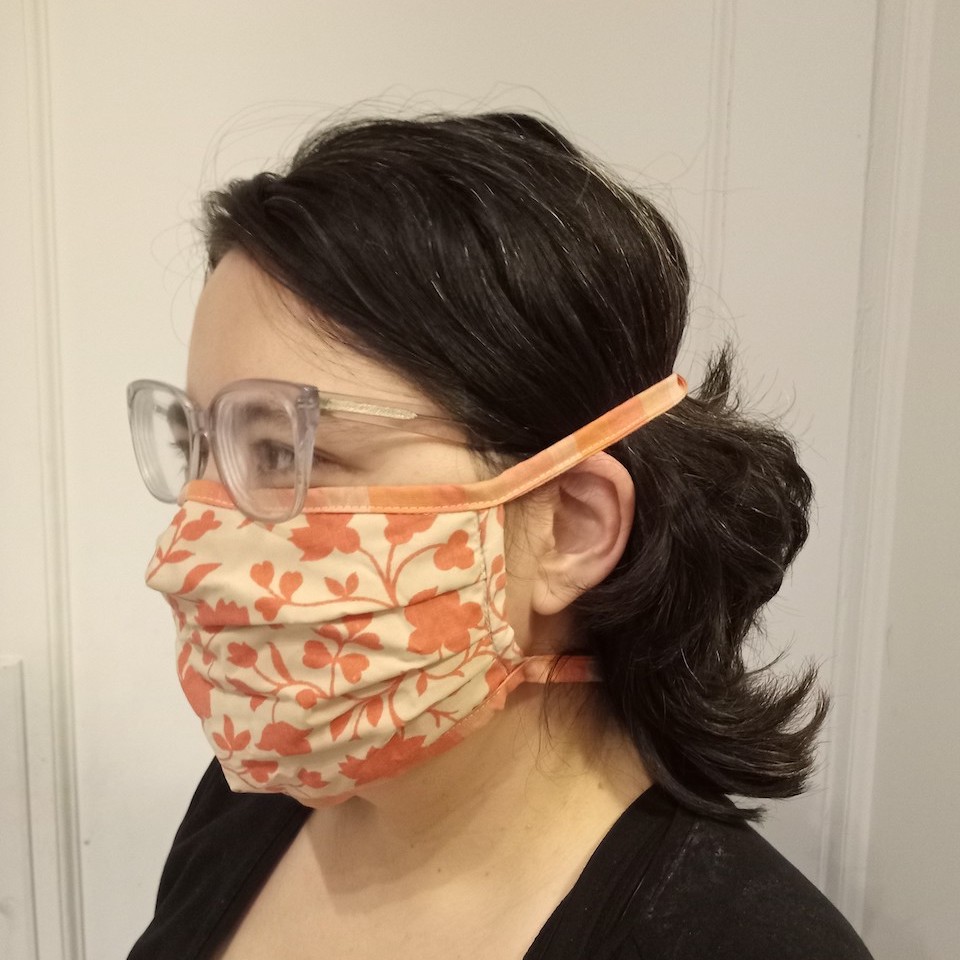

| These masks were produced based on advice from Open-Source COVID19 Medical Supplies. They are made of 2 layers of 100% cotton fabric. The masks have been stitched together using [insert your thread type here] thread. These masks are intended to be worn over existing PPE to prolong the life of surgical masks or N95 masks. These masks should be washed before use. They are suitable for use in contaminated environments but are not sterile. Do not touch the side that goes against your face. |

|---|

NYC Face Mask Initiative (NYCFMI) production is on pause and the dropbox system has been retired in anticipation of a second wave.

NYC Makes PPE still has reusable masks that we can deliver.

Find the project documentation here: Sewn Masks For NYC Hospitals

Turban Project Fabric Mask

This is a sewn mask pattern, available via Deaconess Hospital. Instructions and patterns are available here: [external link]

A.B. Mask

This design was vetted with the Skilled Laborers Brigade and is being manufactured in NYC. Instructions are available here: [External Link]

Operation We Can Sew It

This sewn mask project started to connect volunteers with Denver’s SCL Health System and Saint Joseph Hospital to protect medical workers during the 2020 COVID-19 Pandemic. Instructions and patterns are available here: [external link]

Alternative Designs:

DIY Paper Mask

This design has not yet been tested - please reach out if you're interested in giving feeback.

This mask concept can be assembled in about 10 minutes using a piece paper. Designed for the general public to avoid using supply that might be needed by hospitals or those who can't otherwise get access to other masks. Instructions are available here: [Internal Link]

Mass Produced Masks

We have our own custom mass-produced masks from the US and Asia, based on the A.B. Mask design. Our Asian masks have latex-free elastic and are in neutral colors for institutions with color restrictions (khaki/white and white/white).

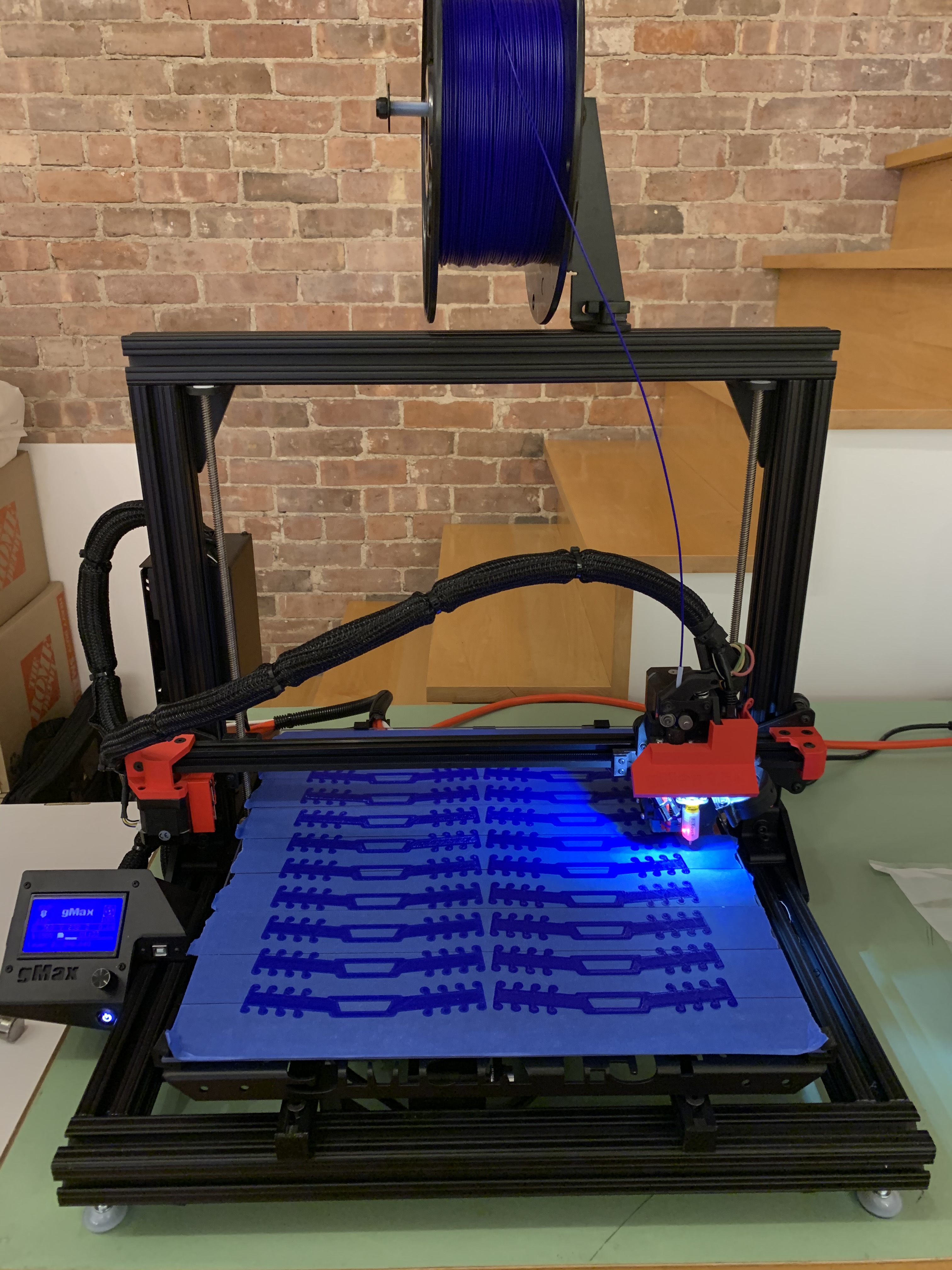

Surgical Mask Tension Release Band for Ear Comfort & Extended Use (Ear Savers)

|  |

|---|

This is a 3D Printed design. Ear Savers help release the tension behind the ears to prevent chafing and move the tension behind the head, where is more comfortable for long-term wear by healthcare and frontline essential workers.

Instructions on how to print these be found on the NIH 3D print exchange below.

3D Model can be downloaded from here: [external link] |

Instructions on how to print it can be found above as well.

We additionally have a 2D model which can be produced using a vinyl or laser cutter both cheaply and in a very green way using vinyl or transparent plastic depending on whether you are using a vinyl or laser cutter.

|

|---|

Model modified by the amazing pink_vampire for producing ear savers using a vinyl or laser cutter can be downloaded from our website

We have a print-out you can use for Ear Savers as well and can be found here.

Inhaler spacers

Inhaler spacers will help COVID-19 patients ensure that the medication is delivered to the lungs, where they needed to help loosen up mucus, and improve lung function as opposed to simply hitting the back the throat and not getting the entire dose to the lungs, where it is needed.

Vase mode Inhaler Spacer by Pink_Vampire

| This is an "Inhaler spacer tube" that they have designed without any sharp corners, easy to use, easy to clean. It is also very fast to print by utilizing "Vase mode" as the printing method. |

|---|

The inhaler has a tapered outlet and because of that, it may work ok regardless, but make sure to print a test unit and check the fit on an actual inhaler before you start printing large quantities.

The larger the nozzle the faster it will print and stronger it will be.

To make it easy to slice they have added the file in 1.2, 0.8, 0.6 wall thickness to work with (1-0.4mm nozzles).

It was tested succesfuly with 1mm and 0.4mm nozzle

The model can be downloaded from here: [external link]

Logistics & Legal

Receiving

We can now accept contributions of 3D printed Ear Savers.

Our shipping address is:

NYC Makes PPE

534 W 112th St

#250877

New York, NY 10025

United States

It is crucial that you follow the directions below.

Manufacturing and Handling PPE

When manufacturing PPE, follow these instructions recommended by Prusa Research:

- Act as if you were infected by the COVID-19 virus. Wear a face mask and a fresh pair of gloves when collecting each batch of printed parts. Store the parts immediately in a sealable bag.

- Talk with whoever you’re making the shields for, let them know about your manufacturing environment.

- There is still debate about how long the virus survives on plastic, but most sources mention 2-3 days. That means that by letting the packed face shields sit for 2-3 days before distributing them, you’ll greatly reduce risk of transmission.

- Do not store the entire stock in one place, minimize the risk of cross-contamination.

One of our members have written a legal disclaimer (with lawyer consultation) to include with face shield donations to hospitals. It is available here:. If you are selling such face shields, you may want to acquire your own legal counsel.